Introduction to Manufacturing Technology & Industrial Materials & Equipment Trends

As manufacturing evolves, the integration of predictive maintenance and AI-driven quality assurance is reshaping the landscape for 2025. Industry leaders like Rimini Street, Han Law, and NGK Ceramics are at the forefront of this transformation, driving innovations in smart manufacturing and supply chain resilience. This article explores the top trends in industrial materials and equipment, providing valuable insights into how these advancements can enhance operational efficiency and sustainability in the coming years.

Table of Contents

Key Takeaways:

- Sustainable materials and energy-efficient manufacturing practices are top priorities for the industrial sector in 2025.

- Smart manufacturing technologies, such as IoT integration and AI applications, are revolutionizing the efficiency and productivity of industrial equipment.

- Advanced materials, including nanomaterials and lightweight composites, are driving innovation and improving performance in industrial applications.

Sustainability in Materials

Sustainability has emerged as a paramount consideration in the manufacturing sector, significantly impacting material selection and production practices.

The objective is to transition towards a circular economy by the year 2025, emphasizing sustainability and minimizing environmental impact.

Recyclable and Biodegradable Options for Enhanced Environmental Impact

The adoption of recyclable and biodegradable materials has markedly increased, with corporations such as Henkel pledging to achieve 100% recyclable packaging by 2025. Other manufacturers are also investigating sustainable alternatives.

For instance, bioplastics such as polylactic acid (PLA) are effective in reducing carbon footprints, as they are produced from renewable resources like corn starch, contributing to sustainability goals.

Companies like Eco-Products specialize in these sustainable materials, offering solutions for food service packaging. The utilization of recycled metals can decrease energy consumption by as much as 95% compared to traditional primary production methods.

Organizations such as Biome Bioplastics and the Sustainable Materials Group provide resources to facilitate the sourcing of environmentally friendly materials, thereby assisting businesses in their transition toward sustainability.

Energy-Efficient Manufacturing Practices

Implementing energy-efficient practices can result in a significant reduction of operational costs, with potential savings of up to 20%, as demonstrated by companies transitioning to renewable energy sources, a key aspect of energy management.

To initiate this process, manufacturers should conduct comprehensive energy audits to identify areas of inefficiency. This approach can be further enhanced by investing in renewable energy solutions, such as the installation of solar panels, which typically provide a return on investment within a timeframe of five to seven years.

Furthermore, the utilization of energy management systems, such as Schneider Electric’s EcoStruxure, can optimize energy consumption by offering real-time data for tracking usage and savings. It is essential for companies to assess their energy savings by comparing baseline energy consumption with post-implementation data, thereby ensuring that their strategies deliver the anticipated financial benefits.

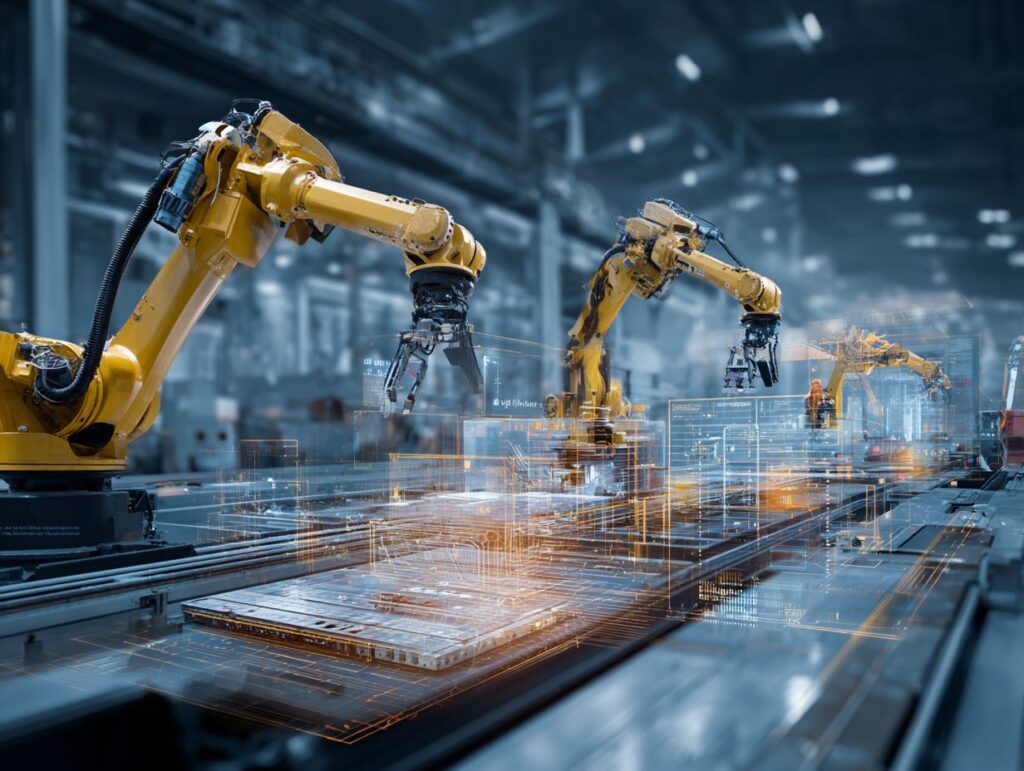

Smart Manufacturing Technologies and Digital Transformation

Smart manufacturing technologies are transforming the industry, with the integration of Internet of Things (IoT) and digital tools expected to enhance productivity by as much as 30% within the next few years.

IoT Integration in Equipment for Real-Time Insights

The integration of Internet of Things (IoT) technology within manufacturing equipment facilitates real-time monitoring and data analytics, resulting in enhanced operational efficiency and reduced downtime.

Manufacturers may initiate this process by employing sensors to gather data regarding machine performance and environmental conditions. For example, the installation of temperature and vibration sensors can assist in identifying potential issues before they escalate into more significant problems.

Platforms such as Siemens MindSphere provide detailed analytics, transforming raw data into actionable insights. A notable case study involves an automotive manufacturer that achieved a 30% reduction in equipment failures and an increase in production by implementing predictive maintenance strategies.

By addressing issues based on real-time data, this manufacturer significantly minimized operational disruptions and optimized their workflows.

AI and Machine Learning Applications in Quality Control

Artificial intelligence (AI) and machine learning are significantly transforming quality control processes, with predictive analytics demonstrating the capability to reduce defects by as much as 50% in manufacturing, enhancing product quality.

Machine vision technologies are revolutionizing product inspection by employing AI algorithms to identify defects in real-time. For example, systems such as IBM Watson facilitate streamlined image analysis, allowing manufacturers to uphold high-quality standards.

Predictive analytics tools like TensorFlow utilize historical data to forecast inventory requirements, effectively minimizing stockouts and excess inventory.

Through the integration of these advanced technologies, manufacturers can enhance operational efficiency while significantly improving product quality, ultimately leading to increased customer satisfaction.

Advanced Materials Development and Manufacturing Trends

The development of advanced materials is essential for improving product quality and efficiency, as nanomaterials present innovative applications across various industries.

Nanomaterials and Their Applications in Manufacturing

Nanomaterials are increasingly being integrated into manufacturing processes to enhance product durability and performance, particularly in sectors such as aerospace and automotive, driven by manufacturing trends.

For example, Boeing employs carbon nanotubes in their aircraft components, which significantly improves strength while simultaneously reducing weight. This innovation leads to enhanced fuel efficiency and lower operational costs.

Similarly, companies like Ford are exploring the use of graphene-infused plastics to improve thermal stability and impact resistance. The adoption of these advancements enables manufacturers to produce lighter and stronger vehicles that comply with stringent regulatory standards, thereby enhancing overall safety and performance.

Consequently, investing in nanotechnology can provide a distinct competitive advantage in terms of product innovation and sustainability.

Lightweight Composites for Efficiency and Cost Reduction

The utilization of lightweight composites has the potential to reduce vehicle weight by as much as 30%, leading to significant energy savings and enhanced performance.

In the automotive sector, companies such as Ford have successfully integrated carbon fiber into their vehicle designs, resulting in a 15% improvement in fuel efficiency. Similarly, in the aerospace industry, Boeing’s 787 Dreamliner employs composite materials to achieve weight reduction and optimize aerodynamics, culminating in a 20% decrease in fuel consumption.

Research indicates that the adoption of lightweight composites can lower manufacturing costs by up to 15%, attributable to reduced material consumption and enhanced production efficiency. Consequently, these materials are increasingly favored for their cost-effectiveness and performance benefits.

Regulatory Changes and Compliance

Regulatory changes are progressively influencing the manufacturing landscape, as global standards necessitate compliance to improve product quality and safety, crucial for IoT integration.

Impact of Global Standards on Equipment and Process Optimization

Global standards, such as ISO 9001, require equipment compliance to ensure consistent quality across manufacturing processes.

To maintain compliance with ISO 9001, manufacturers should adopt a structured approach. Initially, it is essential to conduct a comprehensive audit of existing equipment to identify any discrepancies with established standards. This can be accomplished using tools such as internal checklists or ISO compliance software.

Subsequently, manufacturers should establish a routine documentation process for maintenance and calibration logs, ensuring that all adjustments are meticulously recorded. Regular training sessions for staff on compliance requirements are also crucial to keep all personnel informed and prepared.

Adhering to these steps not only ensures compliance but also enhances overall equipment efficiency.

Market Dynamics, Economic Factors, and Talent Challenges

Market dynamics are undergoing significant changes as a result of various economic factors, notably the ongoing supply chain challenges underscored by the 2024 port strike, which are impacting manufacturing operations on a global scale.

Supply Chain Resilience and Logistics Optimization

Building supply chain resilience is crucial for manufacturers to effectively mitigate the impacts of disruptions such as material shortages and transportation delays.

One effective strategy to achieve this goal is to diversify the supplier base. Instead of relying solely on a single supplier from a specific region, manufacturers should integrate multiple suppliers from various geographical areas, enhancing supply chain optimization.

Additionally, implementing data visibility solutions, such as Supply Chain Control Towers, can provide real-time insights that facilitate proactive decision-making.

It is also imperative to develop contingency plans that encompass alternative sourcing options and emergency response strategies.

To evaluate performance, it is advisable to track key metrics such as lead times, order accuracy, and inventory turnover, thereby enabling continuous improvement in supply chain resilience.

Cost Trends in Raw Materials: Navigating Economic Shifts and Smart Manufacturing Trends

Tracking cost trends in raw materials is essential for manufacturers, as prices are projected to increase by 10% in 2024 due to inflation and supply chain pressures. Manufacturers can leverage resources such as Bloomberg for real-time pricing data and MetalMiner for comprehensive trend analysis.

To effectively manage costs, it is advisable to consider the following strategies:

- Renegotiating contracts with suppliers, leveraging AI-driven quality insights.

- Diversifying sources of materials through IoT integration and hyperautomation.

Additionally, regularly reviewing procurement strategies and implementing just-in-time inventory systems can further assist in minimizing costs. Utilizing forecasting models that account for seasonal fluctuations can enhance budgeting accuracy.

By integrating these strategies, manufacturers can better position themselves to mitigate risks associated with rising material costs and improve energy efficiency for their manufacturing clients.

Learn more, 10 Manufacturing Trends in 2025 That Will Shape the Future.

Frequently Asked Questions

What are the top trends in industrial materials and equipment for 2025, including Industry 4.0 and Industry 5.0?

The top trends in industrial materials and equipment for 2025 are increased use of automation and robotics, growth of 3D printing technology, focus on sustainability and eco-friendly materials, rise of the Internet of Things (IoT) in industrial equipment, advancements in nanotechnology, increased use of virtual and augmented reality in design and production processes, and the impact of cyber-physical systems and smart factories.

How will automation and robotics impact the industrial materials and equipment industry in 2025?

Automation and robotics will greatly impact the industrial materials and equipment industry in 2025 by increasing efficiency and productivity, reducing labor costs, and improving safety in manufacturing processes. With advancements in artificial intelligence and machine learning, these technologies will also be able to adapt and optimize production processes in real-time.

What role will 3D printing technology play in the industrial materials and equipment industry in 2025?

In 2025, 3D printing technology will continue to revolutionize the industrial materials and equipment industry by allowing for rapid prototyping and customization of products. This will lead to faster production processes, cost savings, and the ability to create more complex and intricate designs without the limitations of traditional manufacturing methods.

Why is sustainability becoming a top trend in the industrial materials and equipment industry for 2025?

Sustainability is becoming a top trend in the industrial materials and equipment industry for 2025 due to the increasing global focus on reducing carbon emissions and creating a more environmentally friendly manufacturing process. This trend is also driven by consumer demand for sustainable products and the potential cost savings that come with using eco-friendly materials.

How will the Internet of Things (IoT) impact the industrial materials and equipment industry in 2025?

The Internet of Things (IoT) will play a significant role in the industrial materials and equipment industry in 2025 by allowing for connected and smart equipment that can communicate and share data in real-time. This will lead to improved maintenance and performance monitoring, reduced downtime, and more accurate predictive maintenance.

In what ways will advancements in nanotechnology impact the industrial materials and equipment industry in 2025?

Advancements in nanotechnology will have a significant impact on the industrial materials and equipment industry in 2025 by allowing for stronger and more lightweight materials, improved wear and corrosion resistance, and increased durability in extreme conditions. This technology also has the potential to create new and innovative materials with unique properties for various industrial applications.